Products

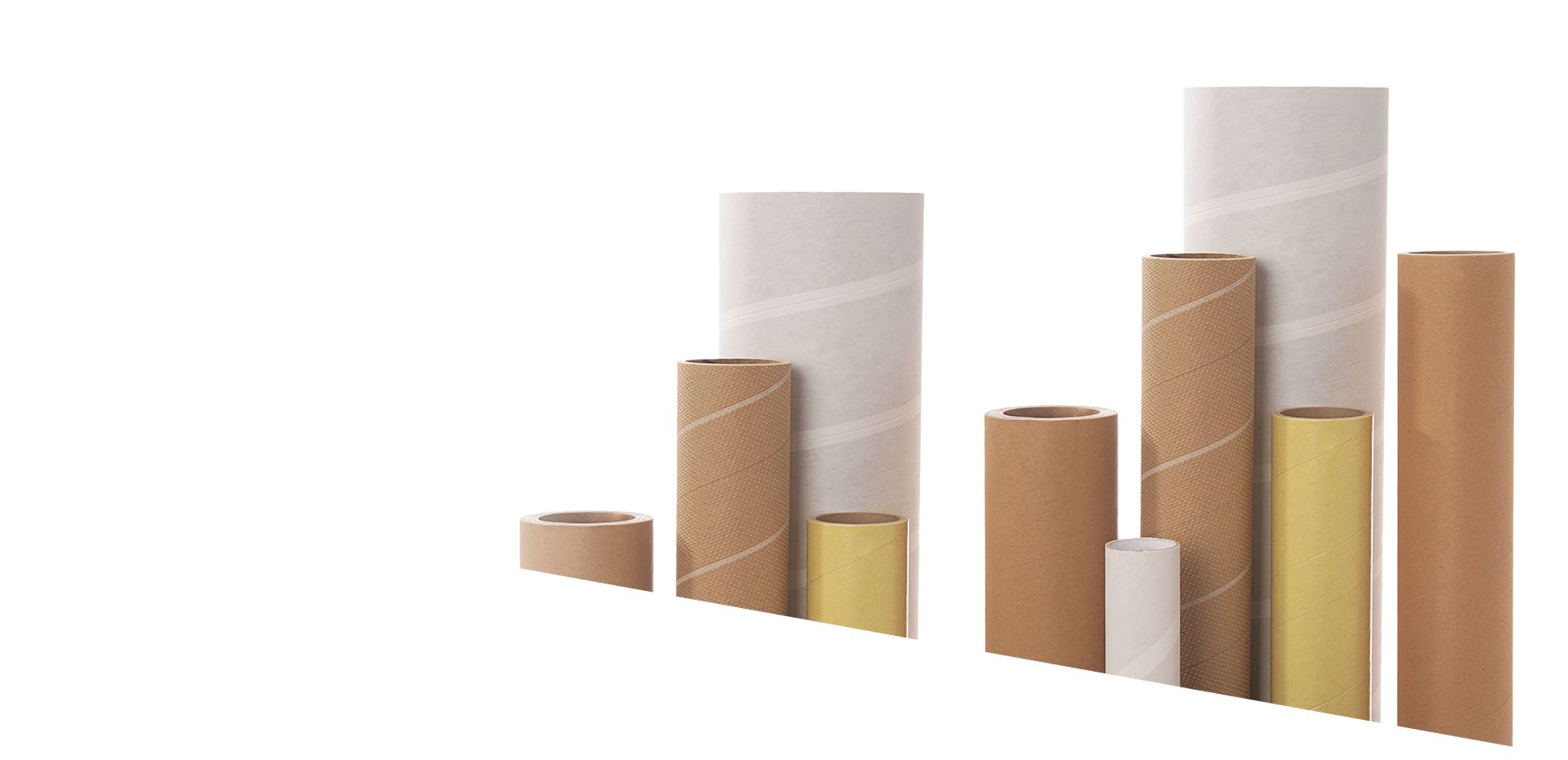

Our spirally and parallel-wound hard paper cores serve as carriers for web materials and are used in the film and foil industry, by paper manufacturers and finishers or in the textile industry.

Our spirally and parallel-wound hard paper cores serve as carriers for web materials and are used in the film and foil industry, by paper manufacturers and finishers or in the textile industry.

However, they are also used as packaging and shipping tubes and for other applications. The product range of GROSS HOF in this area covers both standard tubes, tubes with a wound flag or adhesive strips as well as special tubes for the highest demands.

The surfaces – for example non-stick coated, embossed, smooth or tape-resistant – are adapted to the individual requirements of the customer.

The possibility of "in-line" drying for thin cores and winding tubes from GROSS HOF creates the prerequisite for extremely short throughput times while maintaining the required quality standards. Heavy cores are dried using a computer-controlled chamber. This guarantees fast delivery and enables our customers to plan their core needs in a timely manner.

Technical informations – Download

Whether for label or adhesive tape manufacturers, whether for manufacturers of textile tapes or foils - wherever narrow webs are wound, core rings from GROSS HOF are used. These are also used as pallet feet or support and adapter cores.

Our core rings are manufactured on the most modern cutting machines, which means that burr-free and clean edges and the most precise manufacturing tolerances can be achieved.

Core rings from GROSS HOF are manufactured according to customer requirements in a wide range of widths, diameters and wall thicknesses, with an inner layer printed in one or more colours or with surfaces tailored to the respective application and are therefore the right choice for every application.

Whether small batch sizes or large quantities - we supply you according to your needs.

Technical informations – Download

Know-how and our experience in the production of cylindrical textile cores as well as good contacts to machine manufacturers give us the necessary competence to offer products that meet the high requirements when used on modern spinning and winding machines.

Man-made fibre cores from GROSS HOF meet the highest demands in spinning, texturing, the production of glass filaments or BCF yarns. Surfaces suitable for applications, such as parchment, crepe or embossed cover sheet, improve the run-off properties during further processing.

Innovative and economical solutions in the design of thread catch and clamping slots, notches and grooves increase productivity during yarn production and thereby reduce the costs of our customers.

We test our high-speed spinning cores, which are exposed to extreme loads of up to 8,000 m/min, on a BARMAG winding head.

Technical informations – Download

Decades of experience, precise knowledge of the requirements and production on modern systems ensure a high level of quality and problem-free use of our conical cross winding and cylindrical rotor tubes. We offer our customers all standard formats that are common for the latest ring, rotor spinning and winding machine generations, but we can also implement special designs according to customer requirements.

Surfaces adapted to the application, such as a crepe cover sheet for the cylindrical rotor tubes or velour grinding and grooving for the conical cross winding tubes, enable high take-off speeds during further processing of the yarn.

A wide variety of colours and a large number of print symbols enable our customers and their buyers to distinguish clearly between different yarn types and spinning batches.

Steam-resistant cones with a highly wet-proof finish complete our range and are a cost-effective alternative for this purpose.

Technical informations – Download